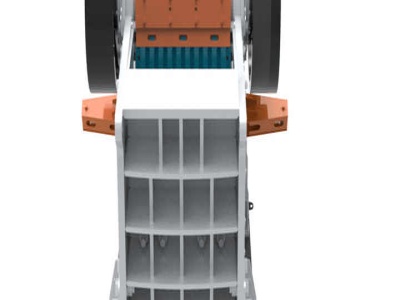

principle operations of a jaw crusher

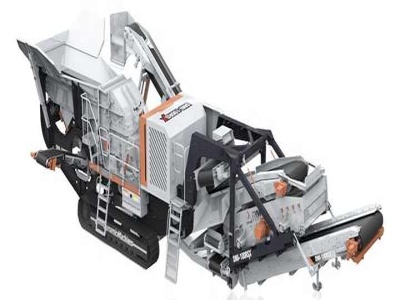

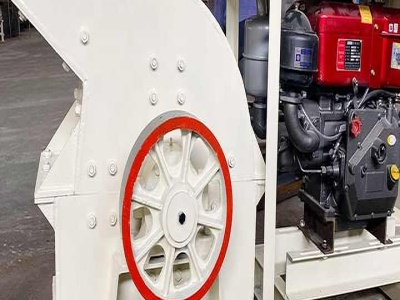

principle operations of a jaw crusher. Home; product; principle operations of a jaw crusher; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; .