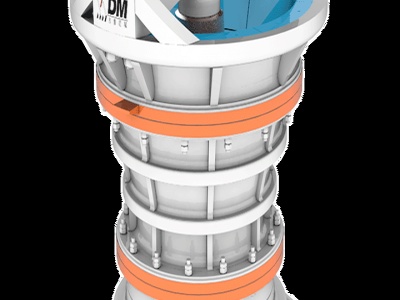

Test work – for optimised gravity separation processes

At FLSmidth, we understand the importance of efficient test work when confirming the applicability of gravity separation for a given ore body. We also recognise the consequences that poor testing processes can have, such as incorrect equipment selections – the addition of a gravity circuit when it is not needed – and nonrepresentative sample data that leads to illinformed recommendations.