The Gold Smelting Process

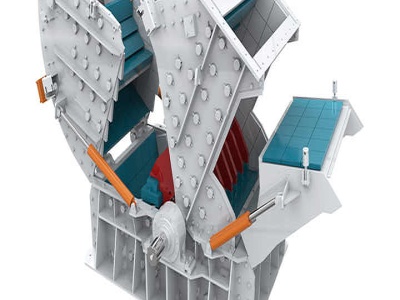

· The first step in gold smelting involves processing the gold ore. The ore containing gold once mined from the earth is processed by separating gold minerals from the crude matter holding the ore together. The gold ore is then pulverized using pressure to create very fine particles. These fine particles are then heated in a furnace to temperatures above 1064 degrees Celsius the melting point .