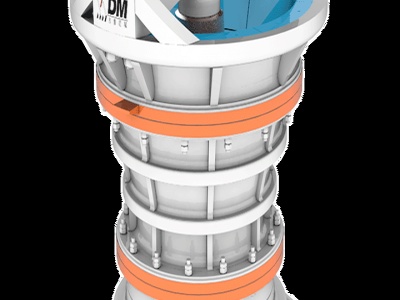

hydraulic vibratory screen motors

Martin ® Industrial Vibrators. MARTIN ® is the leader in Industrial Vibrators and vibration systems and solutions for a wide range of manufacturing industries. We provide electric vibrators, pneumatic vibrators, hydraulic vibrators, bin vibrators, railcar vibrators, vibratory feeders and a host of other products to make material flow easy.