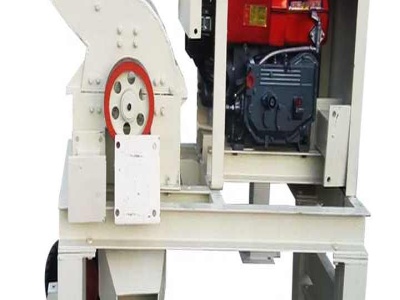

Effective impact crushers for cement plants | FLSmidth

A reliable and durable crusher is the foundation for delivering consistent feed to your raw mill – and highquality, dependable feed is the bedrock for an efficient cement production process. Our experienced engineers work closely with you to ensure that your impact crusher supports your goals, which starts with considering the composition of your raw materials.