ball mill screening product

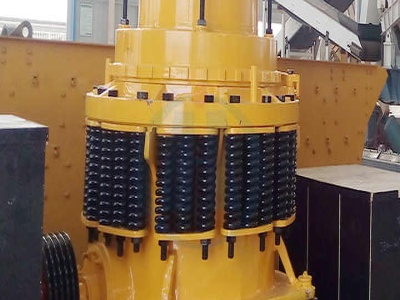

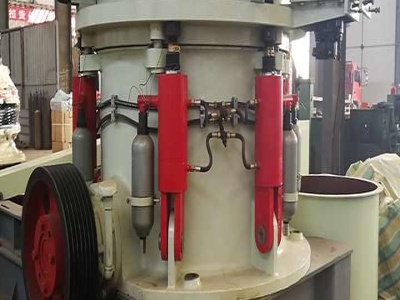

ball mill screening product. Ball Mill Model of Ball Mill Rod Mill Manufacturer of Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening and part or all crushing and grinding of rod mill or ball mil