Ball mill – CHUKOH SEIKI CO., LTD.

Ball Mill (Wet Type) Add crushed raw materials and grinding media (balls), water and other liquids to the mill. Although it is more suitable for pulverization than dry type, it is suitable for fine grinding, but if it crushes too long, contamination of impurities may increase due to wear of liner and ball.

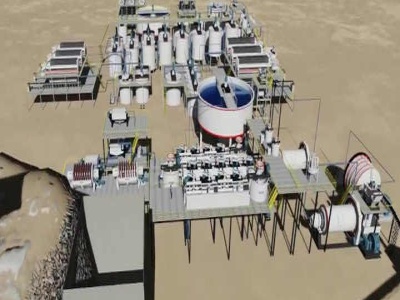

![[ wet type carbon black magnetic separator with ball mill ]](/um7yinb/705.jpg)

![[ wet type carbon black magnetic separator with ball mill ]](/um7yinb/696.jpg)