hpgr in copper process

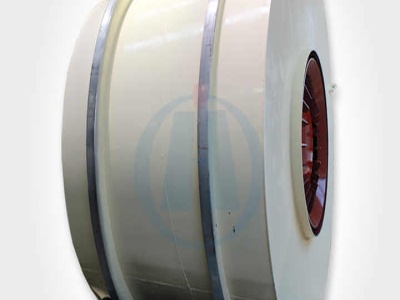

Two key characteristics of copper and gold ore crushed by High Pressure Grinding Rolls more fines and micro cracks result in much better recovery rates than conventionally crushed ores. Chat (HPGR) high pressure grinding rolls/rollers for cement, ores ...