Portable Crushing Equipment Sales and Rental | Thompson ...

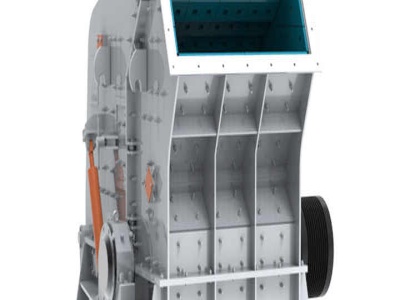

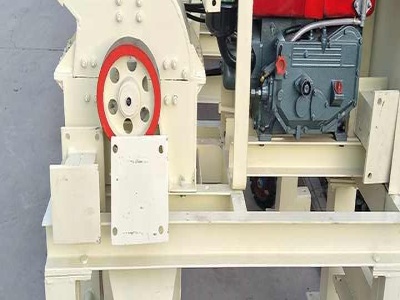

Jaw Crushers exert more crushing power and are the best choice for very hard rock like granite and abrasive rock. Secondary Crusher. A secondary crusher is one that takes crushed material out of a primary crusher and reduces the product further. An impactor or a cone crusher can be used as a secondary crusher.