iron production process in sinhala

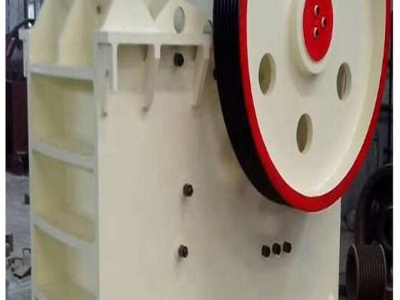

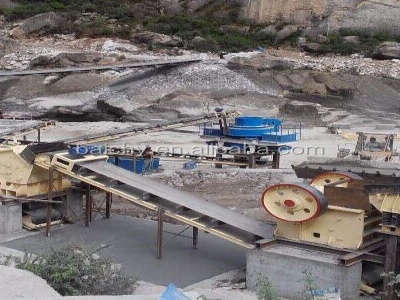

iron production process in sinhala As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.