Humphrey Spiral Iron Ore Concentrator

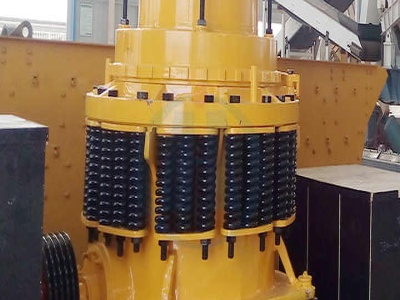

Iron ore spiral concentrator . spiral concentrator for india iron ore made in china . mar 17, source from jiangxi hengcheng mining equipment co., on spiral concentrator for india iron ore made in china. . and eccentric block and the spring damping device uses steel spiral spring. .. for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore,.