Ball Mill Production Charts

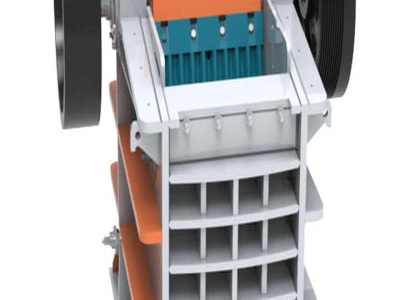

Crusher Production Charts. Ball mill is the key machine to grind the crushed materials Ball mill machine is widely used to process cement silie product building material refractory material fertilizer ceramics and glass etc Impactor crusher production charts impact crusher production chart sajamljubimacaeu impact crusher 911 metallurgist feb 22 2016 as.