United States Environmental Protection Agency General ...

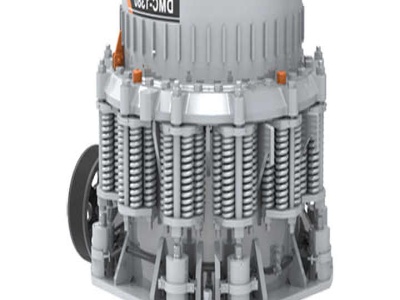

plant by truck, and is dumped into a hoppered feeder, usually a vibrating grizzly type, ... crushing, screening, size classifiion, material handling and storage ... gravel permits require that the operator have a fugitive dust control plan and that fugitive emissions from