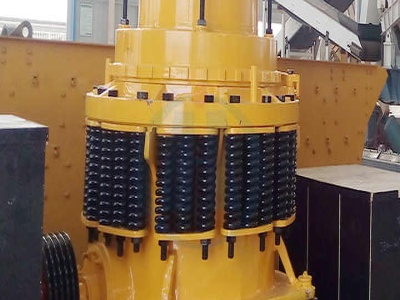

Gyratory Crusher Manufacturers For Coal

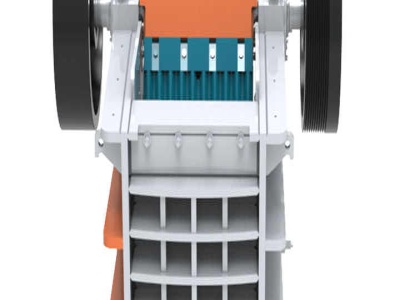

Gyratory crusher manufacturers for crushers, cone/gyratory crushers, feeder breakers, roll crushers and sizers, lt is the largest supplier of limestone crushing plants in the indian cement 400 800 tph semimobile single or double stage coal crushing er crusher manufacturers in india, coal crusher suppliers, indian.