Cement Production Line,Cement Plant,Cement Making Machine ...

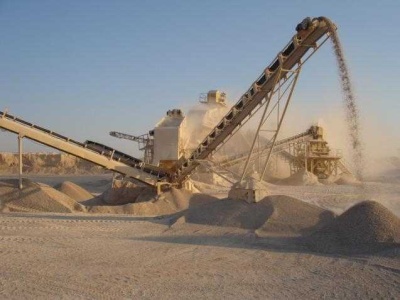

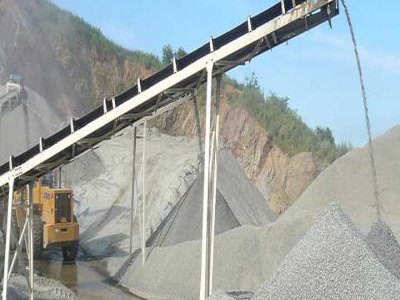

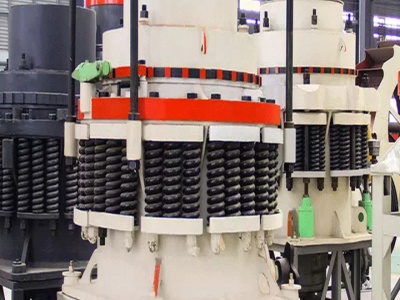

Cement making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill lifer, preheating system, cement rotary kiln and packing machine and so on. All the cement equipment in this line can be provided by our factory.