Rawmill

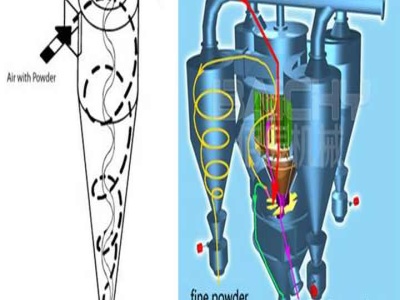

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a .