theory of roll crusher

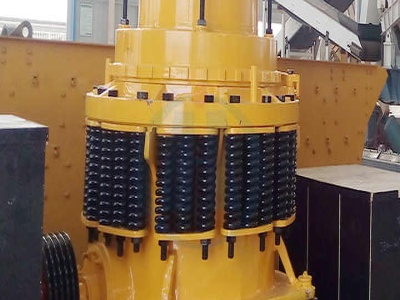

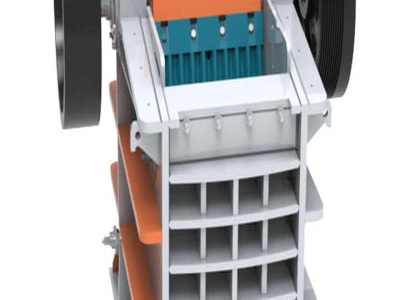

Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock Mineral sizers are a variety of roll crushers which use two rotors with large teeth, on small diameter shafts, driven at a low speed by a direct high...