MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING .

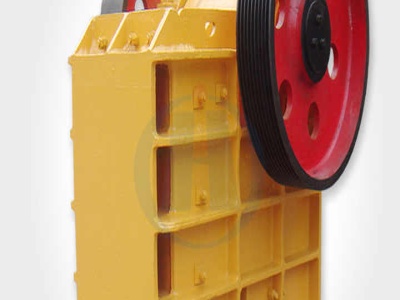

Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product. It is normally measured of the 80% size point, the size at which 80 % of the material passes through the screen aperture. It is given by ℎ = 𝐹 80 𝑃 80 Dynamic Simulation The use of a computer ...