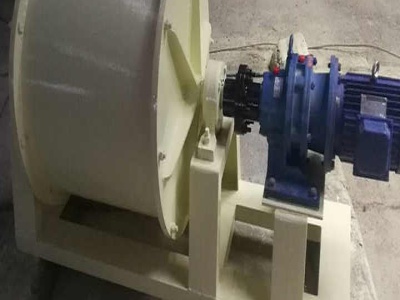

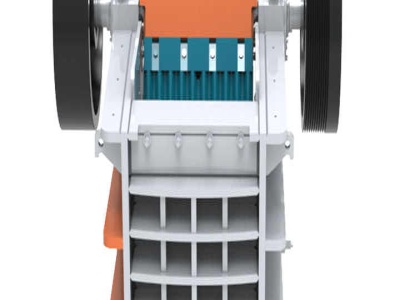

What is Centerless Grinding?

Centerless grinding describes a technique that holds the workpiece in the center between two grinding wheels, which rotate in the same direction (usually clockwise). The left side grinding wheel is held in position as it rotates. The direction of force applied to the workpiece by the left side grinding wheel is downwards towards the platform ...