Introduction to cylindrical grinding processing of the ...

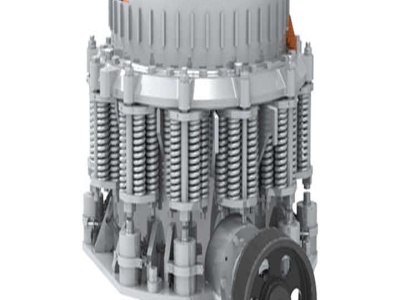

· · Introduction to cylindrical grinding processing of the magnet production. After magnetic property testing of the magnet bank, it will can be into the warehouse if it is good qualified. According to the order requirements, it will can be out into the cylindrical grinder machine workshop. What is the cylindrical grinding of the magnet? For example, when is relatively strict of the customer ...