Jaw Crusher VS Impact Crusher | What's The Difference | MC

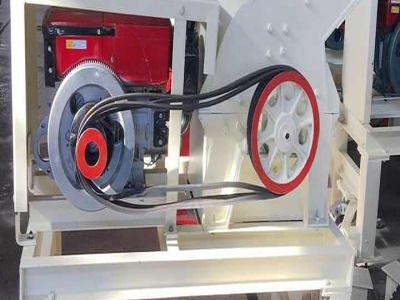

Jaw crusher and impact crusher are the main crushing equipments in the ore crushing production line. Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing of stones.