Metals from Ores: An Introduction

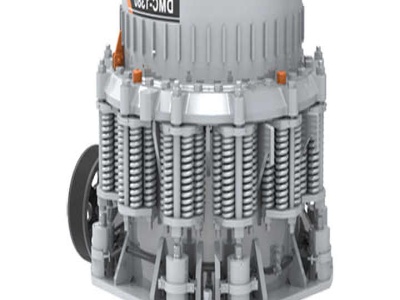

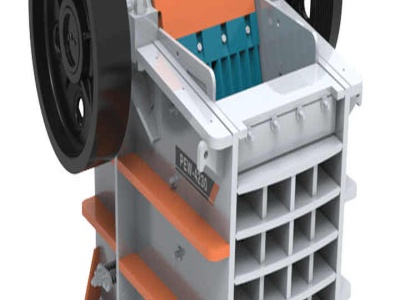

Nickel ores are always associated with cobalt, while lead and zinc always occur together in ores. All other ores are complex yielding a number of ... and grinding then separation of the individual mineral by physical ... the basalt by the natives by crushing and then coldhammering the