how to calculate the power for a 100 tph cement mill

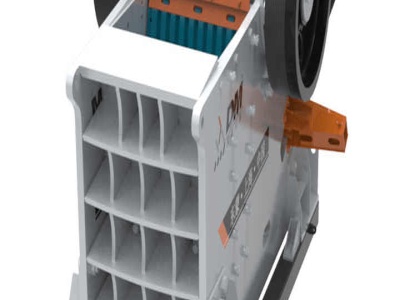

grinding mill capacity tph to 5 tph nigeria how we calculate cement mill tph January 18, 06 By CNMining 39 Comments. formula for calculation of tph in cement mill. how can we calculate a tph of jaw crusher kidzclubin calculate 100 tph stone crushing plant mini crusher how we calculate cement mill tph 100*150 jaw, [More Info] Read More