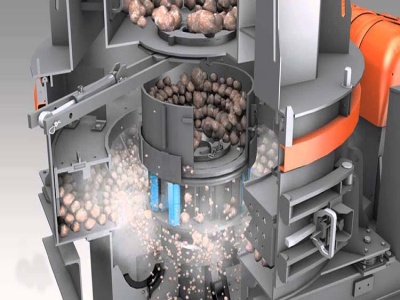

vrm full cement plant

FullTime Manager – VRM Operations (Cement Industry) . As part of the management team take a leadership role toward improved plant safety. Ensuring that the production of the raw meal and cement conforms to quality and production demands.