Cement Manufacturing Process

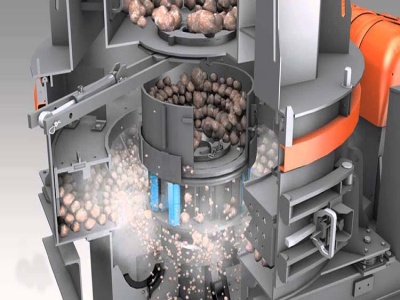

The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches. Secondary crushers or hammer mills then reduce them to even smaller size of 3 inches.