IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY .

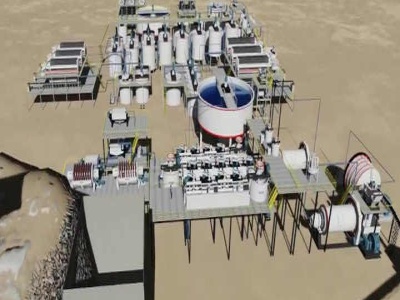

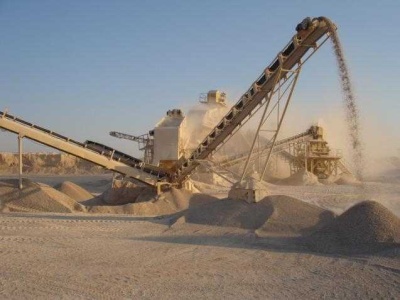

consisting of a tube ball mill and a high efficiency separator was introduced through the matrices of grinding and classifiion. ... Schematics of the Most Common Cement Mills.....41 Figure Tube Ball Mills Used for Cement Finish Grinding. .....44 Figure Arrangement of a TwoCompartment Tube Ball Mill ...