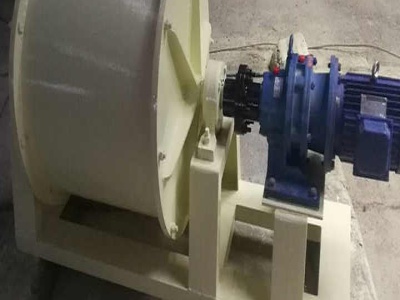

Impact Crusher | Description | Advantages

The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks. In normal types of crusher pressure is generated for the crushing of rocks. But, impact crushers involve an impact method. There is a hopper one .