CASTINGS FORGINGS

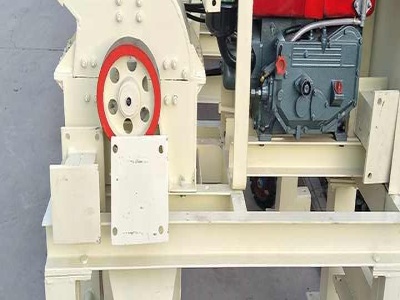

One can easily confirm the reputation of Doosan from the Gizan Cement Plant in Saudi Arabia and the Perak Cement Plant in Malaysia. In addition, Doosan has been supplying heavy steel components for cement and mining equipment, both in domestic and foreign markets in large quantities. Of particular notes, Doosan has the record of supplying the largest kiln tires, supporting roller shafts, and ...