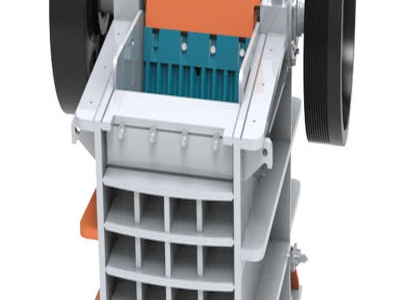

Maintenance and Repair of Jaw Crusher | JXSC Mine

Maintenance of Jaw crusher. Shut down the jaw crusher regularly and check the machine Check the interior parts wear condition at regular intervals, such as feeder pipe, impeller, circular guard plate, wearresistant block, etc. Replace or repair wear parts on time. Periodic inspection of the drive belt The drive belt is indispensable in the jaw crush operating. It is necessary to do belt ...