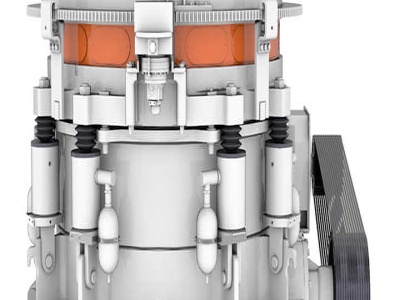

Vertical Roller Mill (60045μm)

Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function. Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries. It has become the mainstream equipment in the pulverizing industry.