Ultrafine carob powder with classifier mill ZPS | Hosokawa ...

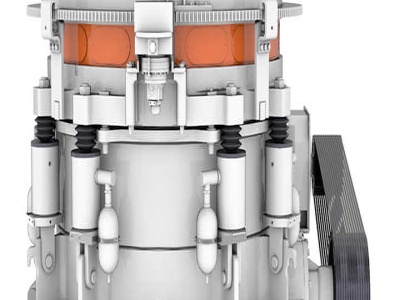

The classifier mill convinces with high throughput rates in the fineness range between 75 and 200 µm at simultaneous low energy consumption. Because at this fineness, carob powder is known to be a dust explosion hazard, the Hosokawa Alpine ZPS installed at Pedro Pérez conforms with the ATEX regulations and is in pressureshockrelieved design ...