Nanosuspensions : Types of Nanosuspension Methods and Various Appliions .

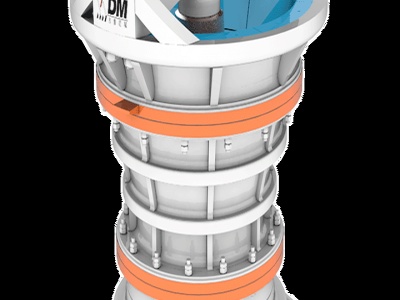

May 24, 2011 · The media mill consists of a milling chamber, a milling shaft and a recirculation chamber. The drug nanoparticles are obtained by subjecting the drug to media milling. High energy and shear forces generated as a result of impaction of the milling media with the drug provide the necessary energy input to disintegrate the microparticulate drug ...