Equipment may include roller crusher, roller crusherdestemmer, destemmerroller crusher, and beaterdestemmer. Licensing/Regulatory Information. Not applicable. PreRequisites. Prerequisite units : FDFCEL2019A. Carry out transfer operations. Employability Skills Information. Employability skills: This unit contains employability skills. Elements and Performance Criteria PreContent. Elements ...

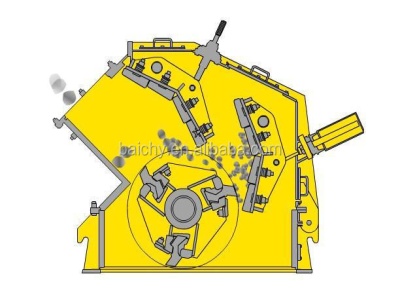

Gyratory crusher operating mechanism

Gyratory crusher operating mechanism. United States Patent . Abstract: This invention relates to improvements in gyratory crushers more particularly to improved mechanism for driving the main shaft of a gyrat6ry crusher. Crushers of this general type are disclosed in my U. S. Patents Nos. 1,754,895, 1,985,098 and 2,208,639 for example.

(PDF) Influence of Operating Conditions and Crushing ...

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has ...

stone crusher carried

stone crusher carried. Jul 28 2020 · The impact crusher is suitable for the production of stone materials for roads water conservancy construction and other industries Different models of impact crushers and highquality parts please click to Get Latest Price The main causes of . Get Price . Our Products. Vibrating Feeder. Vibratory feeder in the production line can transport the material with ...

pdf operation steps of aggregate crusher

Crushing of quarried rock is carried out in stages, with the primary crushing stage typically. Read more. PG 3/16 (12) 6 Sep 2012 ... Figure Outline diagram of a mobile primary jaw crusher (wheeled type) . ... appliions and in the subsequent operation of their installation. ... Reasonable steps will be taken to keep the guidance uptodate to. Read more. INSTRUCTIONS FOR FORM 235 ...

Roll Crushers

· Operation of Roll Crushers. The feed to roll crushers is usually dry. Moisture tends to clog the crusher and could result in the formation of hard crust, which impairs operation. Hence, dry crushing is preferred. Sometimes, water is added between the rolls, which help to prevent formation of the crust and also to remove the hard cake that tends to form on the roll surface. Wet grinding is ...

12 tips to maximize cone crusher productivity

· Operating any crusher "outside" of its designed parameters with either excessive power draw or with excessive crushing force results in a very serious crusher overload. These overloads create something known as "fatigue damage" which is permanent, irreversible and cumulative. Without a doubt, frequent overloads will shorten the life cycle of any cone crusher.

Crusher Equipment

crusher equipment and has designed a specific range of cored wires with wear characteristics to optimise the crushers' performance, reducing maintenance costs. Hardfacing by arc welding is a surfacing operation using a cored wire to extend the service life of specific components. This is carried out preemptively on new

Stone Crushers

· Daily dust monitoring to be carried out by crusher operator. NEVER 1. Run machine without guards in place. 2. Make adjustments or clean moving parts whilst machine is running. 3. Reach into the machine to clean, lubrie or adjust without first shutting off power to engine removing ignition key. 4. Operate the machine while under the influence of drink or drugs. (NOTE: medicines .

Operator, Crusher

To carry out day to day plant operations of Aggregate Crushing by ensuring equipment availability at the crusher, while upholding high standards of safety of the equipment and that of other employees. Specific Job Responsibility. Ensure the KPIs are achieved in the assigned sections. Control the operational activities in the assigned area of operation. Ensure the plant availability in terms of ...

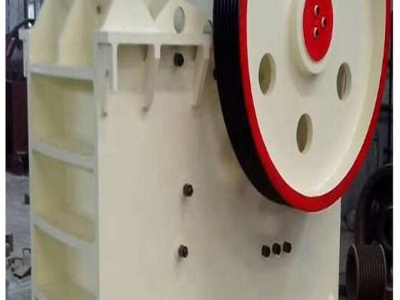

ENGINEERS SAFETY INSPECTION – CRUSHERS SCREENS

SERVICE ENGINEERS SAFETY INSPECTION – JAW CRUSHER. It is important that a machine operator is able to do an "informed" and "knowledgeable check" of the equipment that they are going to operate on an employer's behalf. There are legal requirements under the Provision and Use of Work Equipment Regulations 1998 (PUWER 98), Regulation 6, and ...

Crusher |

Our range includes also clinker crusher. Our capabilities allow us to offer to our clients with turnkey solutions for aggregate crushing systems. We undertake customdesigning, engineering, installation, erection and commissioning of our range of aggregate crushing systems. Our turnkey solutions are carried out by our expert professionals who ensure minimum downtime and accuracy in the project.

Rock crusher for tractor | FAE Group

Stone Crushers. Choose your stone crusher for tractor, for the clearing and recovery of land with stones and rock slabs, even large ones. STCL. Rock crusher for PTO tractors with fixed teeth rotor. from 70 to 150 hp. Find out more. STC. Stone crusher for PTO tractors with fixed teeth rotor. from 80 to 220 hp.

MODULAR

Pilot Modular HSI VSI Crushers Pilot Modular Conveyors Pilot Modular Feeders Hoppers Pilot Modular Accessories Pilot Crushtec Creating solutions for an everchanging industry Standard Plant Solutions Metso Equipment Protection Services A game changer Page: 4 Page: 5 Pages: 67 Pages: 89 Pages: 1011 Pages: 1213 Pages: 1415 Pages: 1617 Pages: 1819 Page: 20 Page: 21 Pages: 22 .

crusher operator training | worldcrushers

· The rock crusher operator must attend training courses before operating the rock crushers. HSE – Quarries – Safe operation and use of mobile . operator crushing plant training. SalaryExpert – Salary Survey, Compensation Data, Salaries . SalaryExpert provides reporting on salaries, total compensation and cost of living by city and state . Mill Operations Technician ― .

Roll Crusher

Roll crusher operation is fairly straightforward: the standard spring rolls consist of two horizontal cylinders that revolve toward each other ... Sample division can be carried out using a number of methods including incremental division, rotary sample division, riffling, fractional shovelling and strip mix and splitting. Incremental division. Incremental division is a manual method of ...

roll crusher operation | Henan Deya Machinery Co., Ltd.

· Roll crusher installation and empty run test 1. Installation of the roll crusher. The roll crusher should not be stacked for a long time in an unventilated place where it is easy to rust. The roll crusher can be installed on a concrete foundation or on the floor of a building. In order to better withstand the uneven force generated by the ...

HSE

The operation of the crusher ches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar). Struck by the loader bucket if the access platform is within the working radius of the loading machine (for 360 degree excavators). Falling if adequate guardrails and access arrangements are not provided. Noise ...

Crushers Operator Training and Certifiion (MCSTRLE10)

Crushers Operator Training and Certifiion (MCSTRLE10) Target Group All identified personnel who are required to use or responsible for work carried out involving the use of Crushers Aim The aim of these courses is to bring candidates into line with accepted Codes of Practice approved by the Health and Safety Commission and regulations covered by the Health and Safety at Work Act 1974 ...

WINE MAKING MACHINES

legislation, the company employer, management and the authorized users operating the MOTORIZED GRAPE CRUSHER AND DESTEMMER Model DMS, DMC, DMCSI, DMCI must supply personnel who will carry out operations of installation, use and maintenance all the necessary information in order to guarantee their safety while using the machine. In particular, they must request and control that all .