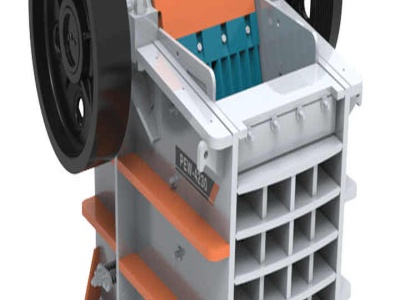

InPitCrushing and Conveying (IPCC)

While there certainly isn't a «onesizefitsall» solution to solve these issues, InPit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience. Although the traditional truck haulage is widely accepted in the mining industry, it contributes up to 60% of the overall mining cost.