10tph manganese ore processing plant

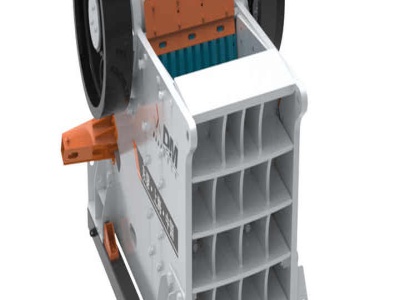

Sep 02, 2021 · Final 3D manganese ore mining process. The materials will feed into the hopper first, via the trough feeder to the jaw crusher. Discharge from the jaw crusher to the vibration screen by the belt conveyor. After separating by the vibration screen, the size +60mm will go to the hammer crusher to control the size to 60mm.