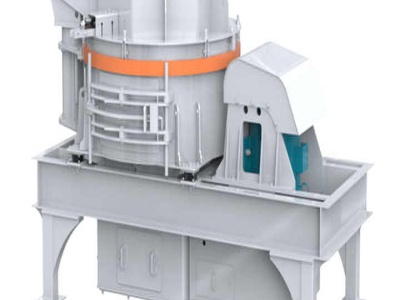

All Direction Three Axis High Energy Planetary Ball Mill ...

Features for All Direction Three Axis High Energy Planetary Ball Mill Threeaxis, alldirection, no dead end of milling, guarantee high milling uniformity. 4 jar design Total Jar Volume: 1 20 L Special gearing design for low operating noise Good for dry, wet, and vacuum .