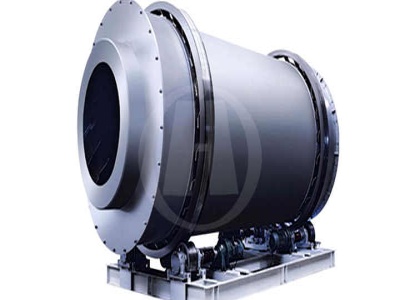

Crusher

Crushing is the process of transferring a force amplified by ... (deformation), each other. The earliest crushers were handheld stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these crushing devices. Background history. Animation of a schematic Newcomen steam engine. – Steam is shown pink and water is blue ...