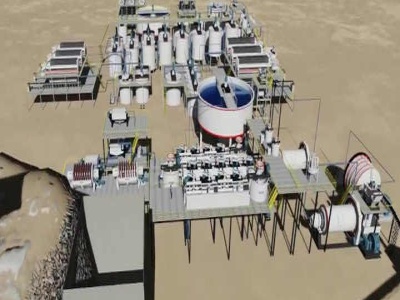

Bottom Ash Grinding Machine

Effects of Grinding Process on the Properties of the Coal. 1 CBA 2 the coal bottom ash was grinded for 2hrs in Los Angeles LA Abrasion Machine and get 3007 passing from 63micron sieve 2 CBA10 the coal bottom ash was grinded for 10hrs in ball mill grinder and get 5075 passing from 63micron sieve 3 CBA20 the coal bottom ash was grinded for 20hrs ...