Commodity Nickel

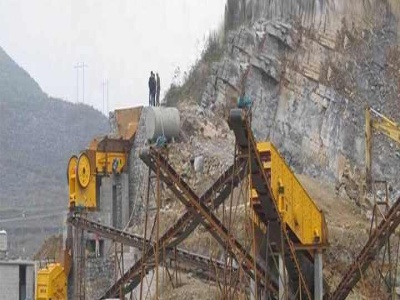

The making of nickel is a process which involves a number of steps: 1. Mining. Nickel mined from lateritic ore is mined from various depths beneath the surface using large earthmoving equipment. The other nickel containing type of ore, sulfidic ore, is usually found in combination with copper ore and is mined underground.