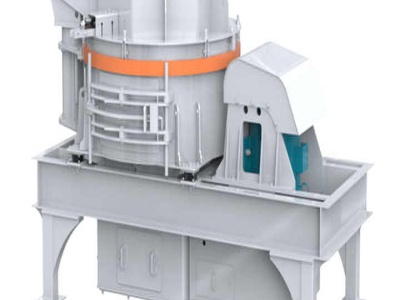

ball mill principle operation theory

ball mill principle operation theory. The ball mill consists of a metal cylinder and a ball the working principle is that when the cylinder is rotated, the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.