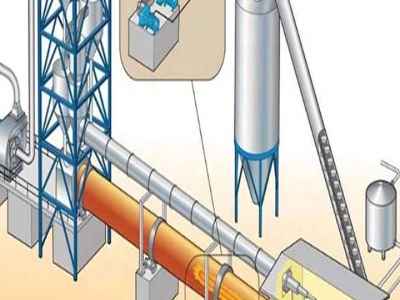

1,000,000TPY Pulverized Coal Production Project in Shandong

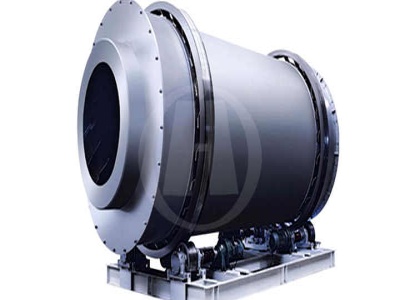

Operation Convenience . To promote the operation convenience of pulverized coal production line, this production line adopts the unique twostep (baking and pulverizing) operation method. The twostep pulverized coal preparation system is a solution with baking and pulverizing separated.