Stone Crusher Used In Cement Industry

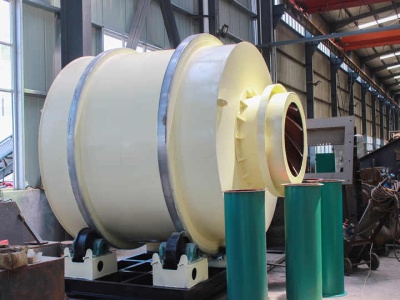

Here focus stone crusher used in cement industry. Stone crusher,be called stone crushing plant. It can used in many industry,such as mining, handle rubbishes,beneficiation. Here focus stone crusher used in cement industry. Cement production line is sample: the big stones in the stone production line are coarsely crushed in the jaw crusher, then ...