Uranium: How is it Mined?

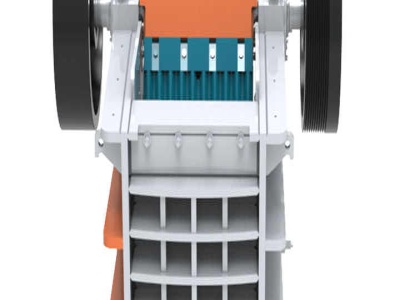

Sep 15, 2021 · Sep 15, 2021 · The milling process involves crushing and pulverizing the rock into very fine fragments and adding water to create a slurry. This slurry is then mixed with sulfuric acid or an alkaline solution to release the uranium from the host rock. Normally approximately 95 98% of the uranium can be recovered from the host rock.