Centrallydriven ball millBAILING® Machinery

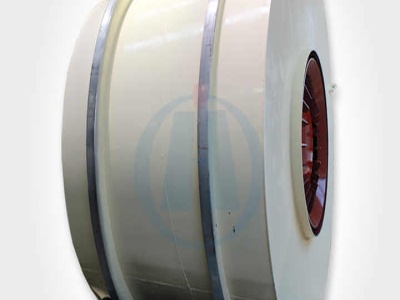

Centrallydriven ball mill adopts largesized doublerow selfaligning roller bearing instead of babbitt alloy bearing with lubriion. After technical improvement,bearing service life becomes longer, sealing becomes better, convenient disassembly and cleaning, and equipped with manual timing refuel, bearing is in good lubriion condition ...