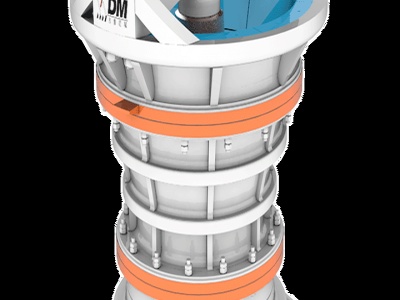

(PDF) Dense Medium Separation (DMS) | Chulodha ...

Introduction Dense medium separation or the sinkand float process is applied to, 1)preconcentration of minerals, Rejection of gangue prior to grinding for final liber action. 2)Used in coal preparation to produce a commercially graded endproduct. Clean coal being separated from the heavier shale or highash coal. Principle This process is simplest of all gravity processes, for separating ...