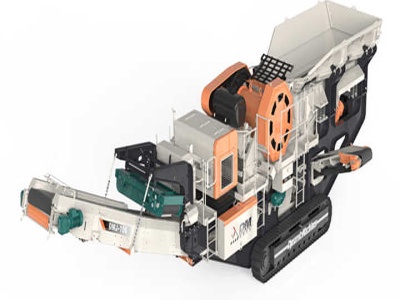

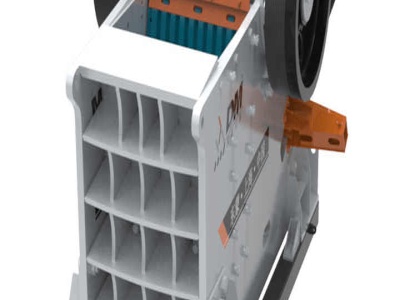

Dust Control For Crushers

Crusher Dust Control Systems [Archive] bulkonline Forums. Dust control is simple and very easy with very low mounted low volume full cone water nozzles at crusher exit points and conveyor transfer points and what wins isA complete invetory of physical plant or plants for crushing and screening systems must be determined/inventoried before you begin.