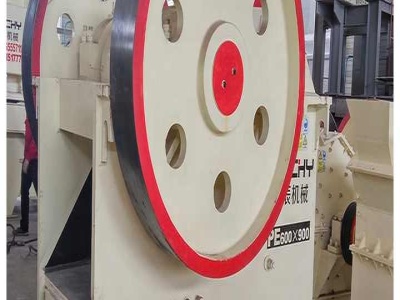

Industrial Solutions Jaw crushers

gletoggle jaw crushers which can be integrated into either stationary or semistationary crushing plants to a model specially designed for integration into roadtransportable plants. The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 possible All data are intended as a guide only. The machine capacity ...