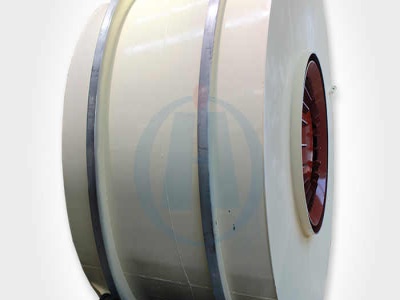

China Mill Liners, Chute Liners, Wear Castings, Wear ...

Wuxi Orient is one of the leading mill liners, chute liners, wear castings, wear plates, grinding media manufacturers and suppliers in China. Our factory will offer you the best mill liners with competitive price. Welcome to contact us.