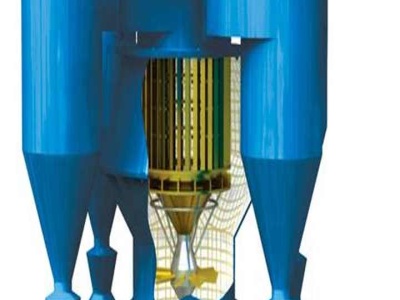

Ball Mill

· · Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.