A new modelbased approach for power plant Tubeball mill ...

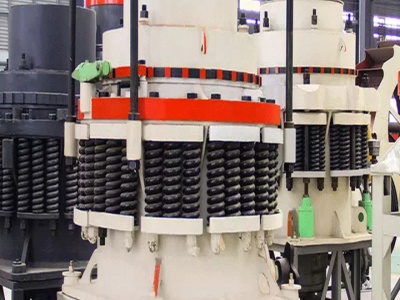

· · Tubeball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry. Compared with the Vertical Spindle mills, Tubeball mills have a much higher grinding capacity. However, there are fewer literatures found in studying Tubeball mill operation compared with the Vertical Spindle mill.